current measurement

The current measuring devices asocontrol measure contactless DC- and AC-currents. The electrical conductor will be wired directly through the measuring device. The galvanic isolation protects the electronic measuring system against current peaks and fault currents. The devices can measure currents up to 100 Amps in effective value (TRMS). It don’t needs a current transformer. The choice of products has 3 types of devices. For special current measurements we engineer special-purpose solutions and make you the suitable control for it. The devices are proven in many applications and are available in the extended temperature range from – 20°C to +50°C.asocontrol acs-s

The device asocontrol acs-s measures DC- and AC-currents up to 100 Amps in effective value (TRMS). In relation to the metering range, both analog outputs supply a value 4-20 mA and 0-10VDC proportional to the measured current. The current measurement is contactless and needs no current transformer. The electrical conductor will be wired directly through the measuring device. The galvanic isolation protects the electronic measuring system against current peaks and fault currents. The devices are available in a extended temperature range from – 20°C to +50°C. The supply voltage is 24VDC. The device is available with the measurement range 60, 75 and 100 Amps.

asocontrol pma-s

The asocontrol pma-s is a active power measurement device for 3-phase grids. In each phase will be measured a electrical power at 15 kW contactless. The amount of all 3 phases is 45 kW. The device measures alternating currents until 65 Amps in effective value (TRMS). In relation to the measure range, both analog outputs supply a value 4-20 mA and 0-10VDC proportional to the measured current. The grid voltage will be adjusted with DIP-switches in the range of 380 to 415 VAC. The current measurement is contactless and needs no current transformer. The three electrical conductors will be wired directly through the measuring device. The galvanic isolation protects the electronic measuring system against current peaks and fault currents. The devices are available in a extended temperature range from – 20°C to +50°C. The supply voltage is 24VDC. The cover is made of steel and protects the electronics ideal against EMC emissions.

asocontrol ucs

The device asocontrol ucs measures DC- and AC-currents up to 100 Amps in effective value (TRMS). In relation to the metering range, both analog outputs supply a value 4-20 mA and 0-10VDC proportional to the measured current. asocontrol ucs are universal applicable. The different devices can detect part load failure and exploits current limits. The measuring signal will be transferred with a analog value or with a Ethernet TCP port. The devices are available in measurement ranges 25, 50, 75 and 100 Amps. The current measurement is contactless and needs no current transformer. The electrical conductor will be wired directly through the measuring device. The galvanic isolation protects the electronic measuring system against current peaks and fault currents.

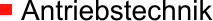

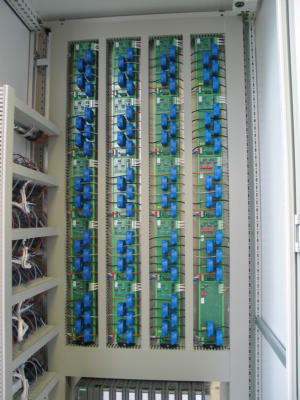

asocontrol design

For special current measurements we engineer special-purpose solutions and make you the suitable control for it.

candle soot measurement

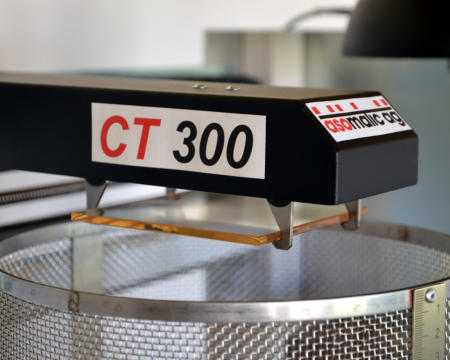

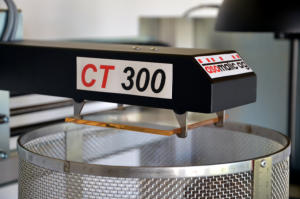

The device CT 300 measures the soot emissions of a burning candle in a normed burning time after DIN standard DIN EN 15426.Measuring method

The device tests the candle qualitiy after DIN standard (DIN EN 15426) in terms the soot development behavior. The device is completely automated except the inflaming. The measured data will be stored in a CSV – file. The DIN standard knows four measuring methods. They are different in candle weight and dimensions. All four measuring methods are implemented in the device.Recipes

The operator can entry the candle dimensions on touch panel and store it as a recipe. The recipe contains all informations about the suitable candle as dimensions, specification and measuring method. With the selection of a candle type the device is automatically setting to the correct measuring method.Test system

The device is based on a sensitive photometry. It is a comparison measurement between a clean and a soiled glass plate. Before the test starts, the device makes a calibration with the glass plate in clean situation. The indicated value will be stored as the reference value. The distance between glass plate and flame is defined in DIN standard. The height adjustment makes the device automatically.Device operation

The operation will solely made on touch panel on the master device. The man machine dialog eliminates wrong operations and requests manual interventions during the measurement. The request for interventions will signalized by a buzzer and a multicolor LED – lamp. Options slave device in combination with a master device heat sensor for flame detecting memory – stick memory card touchpanel measuring basket D = 300 mm candleholder for Candle-light types candleholder for Christmas types modem for remote control device connection to LAN - network embedding additional devices camera etc. Sales Distributor Intercos Handels AG Lavenedelweg 2 www.intercos.ch CH-6280 Hochdorf info[at]intercos.ch

■

■

■

■

■

■

■

■

■

■

maku-DieTool®

The maku-DieTool® - system adjusts automatically the die lip or the retention bar to a desired film thickness. The patented system for die lip and retention bar adjustment is made for flat film and sheet extrusion. The device can mounted on each die. The width maximum is 10 meter. The bolt adjustments are cyclic after thickness values from the film thickness measurement device or manual on touch screen. With the cyclic control you can optimize the manufacturing process and sheet quality, even also the material consumption will be less. Sales Distributor maku AG Flurhofstrasse 13 www.maku-ag.ch CH-6374 Buochs info[at]maku-ag.ch

Kerzenrussprüfung

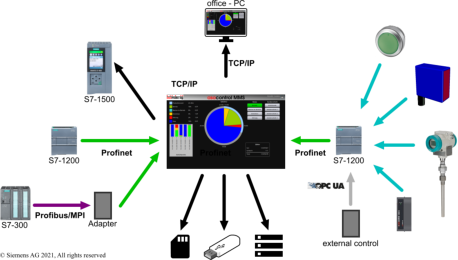

Machine Monitoring System

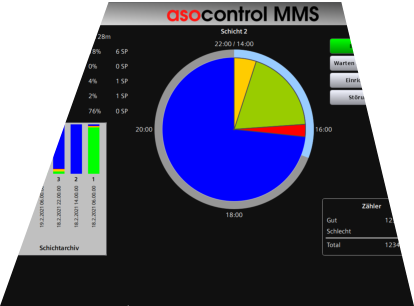

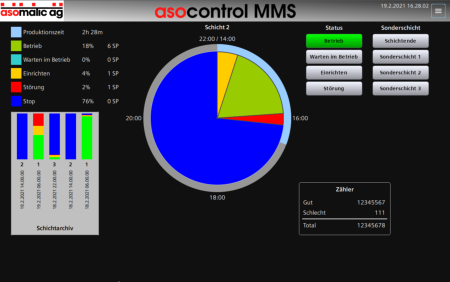

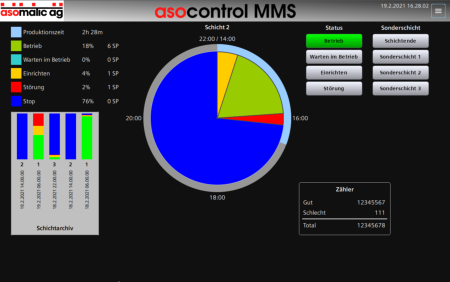

Our asocontrol MMS – monitoring system supplies with little status signals for less money a survey of your production efficiency. The application is running on a conventional Siemens Unified Touch panel from the new MTP – series and can reproduced on a desktop – PC. Collecting process data Visualising process data Operating recipes Memorising data Processing and transferring data LAN – network connection VPN – remote connection Time synchronisation Operating recipes Error- and message memory with time stamp Operating recipes Touchscreen mirroring to a remote – PC Developing data concepts

■

■

■

■

■

■

■

■

■

■

■

■

■

Preparing process data

Process data Machine data Order data

■

■

■

Daten Archivieren

Memory card internal Memory stick external Server connection external csv-data files

■

■

■

■

Remote control

Screen mirroring

■

© Siemens AG 2021, All rights reserved

TCP/IP

Profinet

Profinet

Profinet

Profibus/MPI

office - PC

TCP/IP

current measurement

The current measuring devices asocontrol measure contactless DC- and AC-currents. The electrical conductor will be wired directly through the measuring device. The galvanic isolation protects the electronic measuring system against current peaks and fault currents. The devices can measure currents up to 100 Amps in effective value (TRMS). It don’t needs a current transformer. The choice of products has 3 types of devices. For special current measurements we engineer special- purpose solutions and make you the suitable control for it. The devices are proven in many applications and are available in the extended temperature range from – 20°C to +50°C.asocontrol acs-s

The device asocontrol acs-s measures DC- and AC-currents up to 100 Amps in effective value (TRMS). In relation to the metering range, both analog outputs supply a value 4-20 mA and 0-10VDC proportional to the measured current. The current measurement is contactless and needs no current transformer. The electrical conductor will be wired directly through the measuring device. The galvanic isolation protects the electronic measuring system against current peaks and fault currents. The devices are available in a extended temperature range from – 20°C to +50°C. The supply voltage is 24VDC. The device is available with the measurement range 60, 75 and 100 Amps.

asocontrol pma-s

The asocontrol pma-s is a active power measurement device for 3-phase grids. In each phase will be measured a electrical power at 15 kW contactless. The amount of all 3 phases is 45 kW. The device measures alternating currents until 65 Amps in effective value (TRMS). In relation to the measure range, both analog outputs supply a value 4-20 mA and 0-10VDC proportional to the measured current. The grid voltage will be adjusted with DIP- switches in the range of 380 to 415 VAC. The current measurement is contactless and needs no current transformer. The three electrical conductors will be wired directly through the measuring device. The galvanic isolation protects the electronic measuring system against current peaks and fault currents. The devices are available in a extended temperature range from – 20°C to +50°C. The supply voltage is 24VDC. The cover is made of steel and protects the electronics ideal against EMC emissions.

asocontrol ucs

The device asocontrol ucs measures DC- and AC-currents up to 100 Amps in effective value (TRMS). In relation to the metering range, both analog outputs supply a value 4-20 mA and 0-10VDC proportional to the measured current. asocontrol ucs are universal applicable. The different devices can detect part load failure and exploits current limits. The measuring signal will be transferred with a analog value or with a Ethernet TCP port. The devices are available in measurement ranges 25, 50, 75 and 100 Amps. The current measurement is contactless and needs no current transformer. The electrical conductor will be wired directly through the measuring device. The galvanic isolation protects the electronic measuring system against current peaks and fault currents.

asocontrol design

For special current measurements we engineer special- purpose solutions and make you the suitable control for it.

candle soot measurement

The device CT 300 measures the soot emissions of a burning candle in a normed burning time after DIN standard DIN EN 15426.Measuring method

The device tests the candle qualitiy after DIN standard (DIN EN 15426) in terms the soot development behavior. The device is completely automated except the inflaming. The measured data will be stored in a CSV – file. The DIN standard knows four measuring methods. They are different in candle weight and dimensions. All four measuring methods are implemented in the device.Recipes

The operator can entry the candle dimensions on touch panel and store it as a recipe. The recipe contains all informations about the suitable candle as dimensions, specification and measuring method. With the selection of a candle type the device is automatically setting to the correct measuring method.Test system

The device is based on a sensitive photometry. It is a comparison measurement between a clean and a soiled glass plate. Before the test starts, the device makes a calibration with the glass plate in clean situation. The indicated value will be stored as the reference value. The distance between glass plate and flame is defined in DIN standard. The height adjustment makes the device automatically.Device operation

The operation will solely made on touch panel on the master device. The man machine dialog eliminates wrong operations and requests manual interventions during the measurement. The request for interventions will signalized by a buzzer and a multicolor LED – lamp. Options slave device in combination with a master device heat sensor for flame detecting memory – stick memory card touchpanel measuring basket D = 300 mm candleholder for Candle-light types candleholder for Christmas types modem for remote control device connection to LAN - network embedding additional devices camera etc. Sales Distributor Intercos Handels AG Lavenedelweg 2 www.intercos.ch CH-6280 Hochdorf info[at]intercos.ch

■

■

■

■

■

■

■

■

■

■

maku-DieTool®

The maku-DieTool® - system adjusts automatically the die lip or the retention bar to a desired film thickness. The patented system for die lip and retention bar adjustment is made for flat film and sheet extrusion. The device can mounted on each die. The width maximum is 10 meter. The bolt adjustments are cyclic after thickness values from the film thickness measurement device or manual on touch screen. With the cyclic control you can optimize the manufacturing process and sheet quality, even also the material consumption will be less. Sales Distributor maku AG Flurhofstrasse 13 www.maku-ag.ch CH-6374 Buochs info[at]maku-ag.ch

Machine Monitoring System

Our asocontrol MMS – monitoring system supplies with little status signals for less money a survey of your production efficiency. The application is running on a conventional Siemens Unified Touch panel from the new MTP – series and can reproduced on a desktop – PC. Collecting process data Visualising process data Operating recipes Memorising data Processing and transferring data LAN – network connection VPN – remote connection Time synchronisation Operating recipes Error- and message memory with time stamp Operating recipes Touchscreen mirroring to a remote – PC Developing data concepts

■

■

■

■

■

■

■

■

■

■

■

■

■

Preparing process data

Process data Machine data Order data

■

■

■

Daten Archivieren

Memory card internal Memory stick external Server connection external csv-data files

■

■

■

■

Remote control

Screen mirroring

■